From compliance to competitiveness: Reframing the role of ESG in manufacturing

Fujitsu / October 9, 2024

A remarkable shift is taking place in the manufacturing landscape. According to Fujitsu's recent Sustainability Transformation (SX) Survey 2024 (*1), 77% of organizations now believe that being more sustainable is not just the right thing to do, but it's also good for business. This statistic underscores a growing recognition of the vital role that Environmental, Social, and Governance (ESG) principles play in shaping the future of the industry.

As manufacturers, we face a unique set of challenges in today's world. Regulatory pressures are intensifying, resource efficiency is becoming increasingly critical, and both consumer and B2B customer expectations are evolving at an extraordinary pace. In response to these challenges, Fujitsu has developed an innovative framework: the Value loop. This concept isn't just another corporate initiative; it's a transformative approach that reframes ESG and circular economy practices from mere compliance burdens into powerful drivers of business value and competitive advantage.

Contents

- The Value loop: Fujitsu's framework for sustainable manufacturing

- Transforming ESG reporting into a strategic advantage

- Circular economy: From concept to reality in manufacturing

- Leveraging advanced technologies for sustainability

- Collaboration and partnerships: Amplifying impact

- The path forward: Embracing sustainable manufacturing with Fujitsu

The Value loop: Fujitsu's framework for sustainable manufacturing

At the heart of Fujitsu's approach to sustainable manufacturing lies the Value loop concept. This framework is built on the understanding that true sustainability encompasses three key areas: People, Prosperity, and Planet. It's not only about reducing our environmental impact; it's about creating a holistic system that benefits all stakeholders.

The Value loop creates mutually beneficial relationships between manufacturers, suppliers, customers, and communities. It recognizes that our success is intrinsically linked to the wellbeing of our workforce, the prosperity of our partners, and the health of our planet. This interconnected approach ensures that every action we take ripples outward, creating positive impacts far beyond our factory floors.

Traditionally, digital and environmental strategies have been siloed in many organizations. The Value loop bridges this gap, bringing these strategies together in a powerful synergy. By leveraging technology for both sustainability and efficiency, we can align environmental objectives with initiatives to drive innovation, cut costs, and open new market opportunities.

The Value loop aligns closely with the concept of the "Regenerative Enterprise" – a business model that goes beyond sustainability to actively restore and regenerate the systems it depends on. In this model, manufacturers go beyond minimizing harm; they become a force for positive change in their communities and ecosystems.

Transforming ESG reporting into a strategic advantage

For too long, ESG reporting has been viewed by many as a burdensome compliance exercise – a box to be ticked rather than an opportunity to be seized. This perception often stems from the challenges of collecting and analyzing data related to various scopes of emissions (direct, indirect and those emitted across the value chain), as well as the resource-intensive nature of compiling comprehensive reports.

At Fujitsu, we're changing this narrative. We believe that when approached strategically, ESG reporting can become a powerful tool for driving business value and competitive advantage. Our approach integrates ESG principles directly into core business operations, turning sustainability into a catalyst for innovation and efficiency.

Central to this approach is the Fujitsu ESG Management Platform. This powerful tool goes beyond simple data collection and reporting. It enables:

• Data-driven target setting: Leverage real-time insights to set ambitious yet achievable sustainability goals.

• Visualization and interpretation of ESG data: Transform complex data into actionable insights through intuitive dashboards and analytics.

• Scenario planning and digital rehearsals: Model different strategies and their potential impacts, allowing for informed decision-making.

• Automated reporting and compliance: Streamline the reporting process, freeing up resources for strategic initiatives.

Importantly, our ESG Management Platform doesn't just focus on carbon emissions. It facilitates a holistic transition to a circular economy, helping manufacturers track and reduce their entire environmental footprint – from greenhouse gases to waste management and resource utilization.

The effectiveness of this approach is evident in real-world applications. For instance, AB InBev, the world's largest brewer, partnered with Fujitsu to implement a blockchain-based solution for enhancing transparency in their barley supply chain. This initiative not only improved their ESG reporting capabilities but also strengthened relationships with farmers, enhanced product quality, and opened up new possibilities for sustainable brewing practices. It's a prime example of how ESG initiatives, when properly implemented, can create value across the entire business ecosystem.

Circular economy: From concept to reality in manufacturing

The circular economy represents a paradigm shift in how we approach production and consumption. For manufacturers, it offers a powerful framework for reducing waste, conserving resources, and creating new value streams. But transitioning from linear to circular models can be challenging, requiring new technologies, processes, and mindsets.

At Fujitsu, we're committed to making the circular economy a reality in manufacturing. Our initiatives in this space are wide-ranging and impactful. A prime example is our collaboration with Teijin Limited on recycled materials. This project leverages blockchain technology to create a commercial platform that enhances the traceability and reliability of recycled materials. By providing manufacturers with verifiable information on the environmental impact and origin of materials, we're enabling more sustainable design choices and contributing to a truly circular economy.

We understand the hurdles manufacturers face in transitioning to a circular model, and we've developed a suite of solutions to address these challenges:

• Digital thread for productivity and product lifecycle management: This data-driven architecture enables manufacturers to track a product from conception through to end-of-life, facilitating better design for circularity and more efficient recycling processes.

• Customer experience consulting: We help manufacturers reimagine their customer relationships, moving from transactional interactions to ongoing partnerships that support product longevity and circular business models.

• Advanced technologies for traceability and reclamation: Our IoT and blockchain solutions provide the visibility needed to manage complex reverse logistics and material recovery processes.

By integrating these technologies and approaches, we're helping manufacturers to adapt and thrive in the circular economy. The result is a more resilient, efficient, and sustainable manufacturing sector that's prepared for the challenges and opportunities of the future.

Leveraging advanced technologies for sustainability

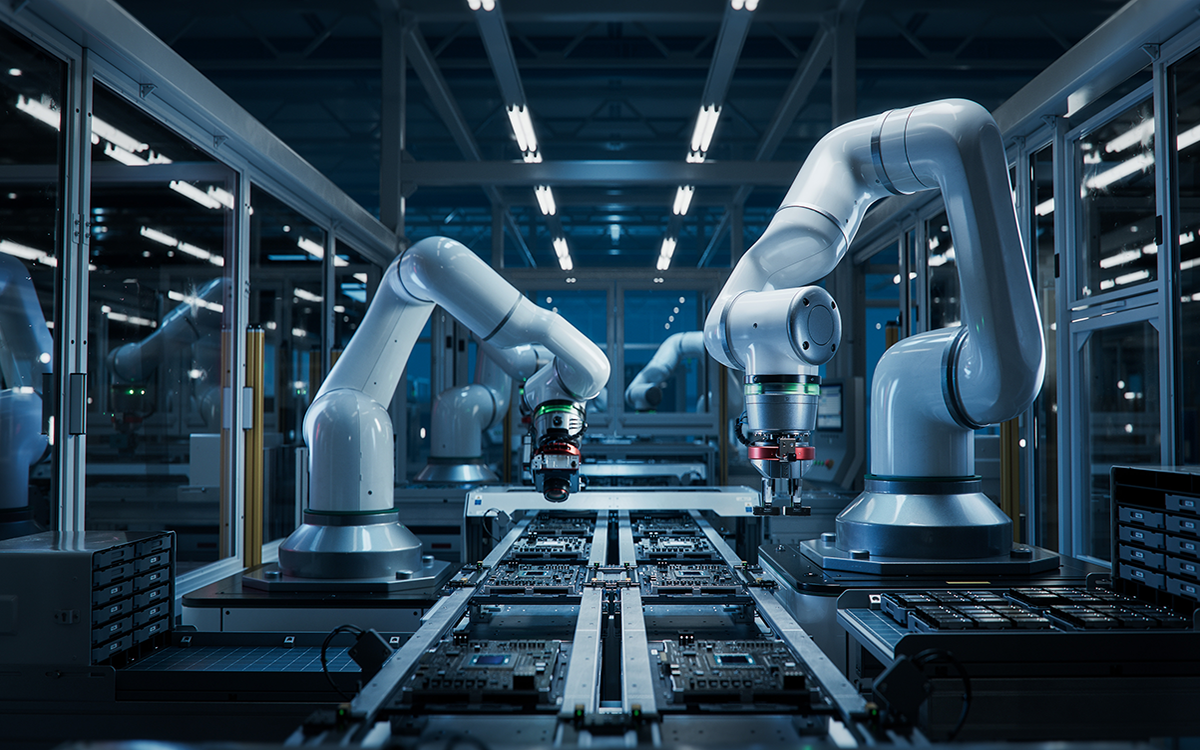

In the quest for sustainable manufacturing, advanced technologies are not just helpful – they're essential. Modern connected technologies are key enablers of circularity, providing the high-fidelity data and control needed to optimize resource use and reduce waste. At Fujitsu, we're at the forefront of applying these technologies to drive sustainability in manufacturing.

Here's how we're leveraging these technologies:

• Artificial Intelligence (AI): AI is revolutionizing manufacturing sustainability. We use AI for data coherence, ensuring that the vast amounts of sustainability-related data generated across operations are consistent and actionable. AI also powers our process optimization tools, identifying inefficiencies and suggesting improvements that can significantly reduce energy consumption and emissions. Moreover, AI-driven predictive maintenance helps extend the life of equipment, reducing waste and improving resource efficiency.

• Internet of Things (IoT): IoT devices are the eyes and ears of the smart factory. We deploy IoT sensors for smart monitoring, providing real-time data on energy usage, emissions, and resource consumption. This granular visibility allows for immediate interventions and long-term strategic planning. Our IoT-enabled energy management systems help manufacturers optimize their energy use, reducing both costs and carbon footprint.

• Blockchain: Transparency and traceability are crucial for sustainable supply chains, and blockchain is the perfect tool for the job. We use blockchain technology to create immutable records of a product's journey through the supply chain, from raw material sourcing to end-of-life recycling. This not only supports ESG reporting but also enables consumers to make informed choices about the products they buy.

These technologies are not just theoretical – they're delivering real results for our clients. For instance, HMD Global, a leading mobile phone manufacturer, partnered with Fujitsu to transition to SAP S/4 HANA. This digital transformation not only streamlined their operations but also significantly enhanced their sustainability performance, earning them a Platinum certification from EcoVadis.

By harnessing the power of these advanced technologies, we're helping manufacturers meet their sustainability goals by enabling them to reimagine their entire business models around principles of circularity and sustainability.

Collaboration and partnerships: Amplifying impact

In the journey towards a more sustainable and circular manufacturing industry, collaboration is essential. The challenges we face are too complex and far-reaching for any single organization to solve alone. That's why at Fujitsu, we place a strong emphasis on partnerships and cross-industry collaboration to drive forward circular economy initiatives.

Our approach to collaboration is multifaceted:

• Strategic partnerships: We've forged key partnerships with industry leaders like SAP, ServiceNow, and Microsoft. These collaborations allow us to deliver comprehensive sustainability solutions that leverage the best technologies and expertise from across the industry. For instance, our partnership with SAP enables us to integrate sustainability metrics directly into core business processes, while our work with ServiceNow enhances asset management and operational efficiency.

• Cross-industry initiatives: We actively participate in and facilitate cross-industry collaborations, recognizing that many sustainability challenges require a coordinated response across value chains. These initiatives often lead to innovative solutions that benefit entire industries.

• Value chain enhancement: Our collaborative approach extends across the entire manufacturing value chain. We work with suppliers, logistics providers, and end-users to create integrated solutions that enhance sustainability at every stage of the product lifecycle.

The power of these collaborations is evident in the results they deliver. For example, our partnership with REHAU Industries, a polymer specialist, led to the development of an AI-powered quality prediction system. This system not only improved product quality but also significantly reduced waste in the production process, demonstrating how technology partnerships can drive both operational excellence and sustainability.

Another success story is our work with Mazda Logistics Europe. By implementing ServiceNow's platform, we helped Mazda achieve a 25% improvement in response time for IT service management. This enhancement not only improved operational efficiency but also contributed to reduced energy consumption and better resource utilization.

These examples illustrate how collaborative approaches, powered by the right technologies and partnerships, can amplify the impact of sustainability initiatives. By working together, we can create solutions that are greater than the sum of their parts, driving the entire manufacturing industry towards a more sustainable and circular future.

The path forward: Embracing sustainable manufacturing with Fujitsu

As we've explored throughout this article, the journey towards sustainable manufacturing is not just about compliance or risk mitigation – it's about seizing opportunities for innovation, efficiency, and growth. Fujitsu's Value loop approach to ESG and the circular economy offers a comprehensive framework for manufacturers to transform their operations and create lasting value for all stakeholders.

The integration of digital solutions is crucial for advancing circular economy practices in manufacturing. From AI-driven process optimization to blockchain-enabled supply chain transparency, technology is the key enabler of the sustainable factory of the future. Our approach ensures that manufacturers are equipped with the necessary tools to not just meet their sustainability goals, but to exceed them and set new industry standards.

But technology alone is not enough. True sustainability transformation requires a holistic approach that encompasses strategy, culture, and collaboration. It demands leadership that sees sustainability not as a cost center, but as a driver of innovation and competitive advantage. This is where our expertise and partnership model truly shines, providing not just technology solutions, but also the strategic guidance and support needed to navigate this complex landscape.

The time to act is now. The challenges we face – from climate change to resource scarcity – are urgent and growing. But so too are the opportunities. Manufacturers who embrace sustainable practices today will be better positioned to thrive in the low-carbon, circular economy of tomorrow.

For those looking to navigate this complex landscape, Fujitsu's Uvance Wayfinders consultancy service offers expert guidance. Drawing on cross-industry expertise and a global R&D commitment, Wayfinders can help you chart a course through the unknown, turning sustainability concepts into tangible business results.

To learn more about how Fujitsu can support your sustainable manufacturing journey, visit our website. Join us in shaping the future of manufacturing – a future that's not just sustainable, but regenerative and thriving.

Editor's Picks