Sustainable AI – Realizing End-to-End Supply Chain Opportunities

Fujitsu / January 16, 2025

The complexity of secure and sustainable supply chains is increasing every day. Improving the management of this complexity with Sustainable AI platforms can be a game changer, increasing efficiency, reducing costs, and improving customer satisfaction.

Contents

- Supply Chains and Logistics Complexity Require Smart Solutions

- Effective and Secure Data Management Provides the Foundation

- AI Use in Supply Chain Management still Low

- Large Retailer have become Forerunner of Sustainable Management

- Partner Support and Improvement of Transport Emissions are Key

- Challenges for Smaller Enterprises

- Support from Industry Initiatives and Research

- Yamato and Fujitsu Demonstrate Sustainable Logistics Potentials

- Conclusion

Supply Chain and Logistics Complexity Require Smart Solutions

In our blog Sustainable AI – Solving the “Double Materiality” Challenge, we discussed the regulatory requirements that companies are facing in their data management starting this year. These challenges are particularly strong in supply chain management. In the EU, the Supply Chain Law (Corporate Sustainability Due Diligence Directive) requires companies to ensure compliance with human rights and environmental standards. Globally, companies are being asked to account not only for their own greenhouse gas (GHG) emissions, but for emissions throughout their supply chains.

Supply chains and logistics have a significant impact on environmental emissions. For most companies, supply chain emissions (Scope 3 emissions) account for more than 70% of their total carbon footprint. For suppliers, the CDP reports that supply chain emissions are 26 times higher than their own operational emissions (Scope 1+2). For retailers, the ratio is as high as 92. This shows how long and complex supply chains have become.

Improving the management of this complexity with sustainable AI platforms can be a game-changer, because it can increase efficiency, reduce costs and improving customer satisfaction. A prerequisite for such gains, however, is that data becomes available at all levels of the supply chain, and that organizations begin to coordinate and optimize product lifecycles "from the cradle to the grave."

Effective and Secure Data Management Provides the Foundation

In our Whitepaper “Sustainable AI for Enterprise Transformation, Innovation and Growth”, we show how the development and implementation of Sustainable AI platforms can become a driving force for enterprise transformation and fostering sustainable growth. It shows how AI, especially generative AI, can integrate with existing management systems to improve prediction, optimization, and planning across multiple business functions. It enables data-driven decision-making and streamlines complex sustainability initiatives across departments and value chains.

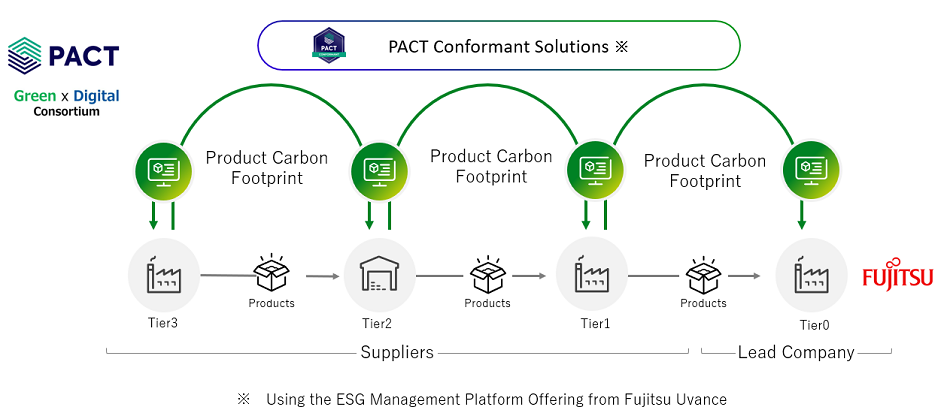

To achieve such integration, systems modernization by moving business functions to the cloud is as important as effective data management that supports seamless and secure data sharing with supply chain partners. Fujitsu had therefore partnered with the World Business Council for Sustainable Development’s Partnership for Carbon Transparency (PACT) to implement the world’s first program to enable business-to-business data integration for product carbon footprint (PCF) information. It succeeded in effectively visualizing CO2 emissions throughout its supply chain with partner companies.

Fujitsu Supply Chain Emission Data Integration

https://www.fujitsu.com/global/about/resources/news/press-releases/2024/1115-01.html

This implementation uses Fujitsu's PACT-compliant solution, Fujitsu Track and Trust, on the Pathfinder Network to link actual data and calculate CO2 emissions in the PCF across the notebook PC supply chain. Fujitsu also identified solutions to real supply chain issues, including how to improve supplier engagement and build ecosystems through PCF data exchange using actual supplier data. Using the technology, it is now working with global suppliers to help decarbonizing entire supply chains.

The knowledge gained from this project and the related development of ESG management platform services that support digital supply chain management is being shared by Fujitsu in its Uvance portfolio for Sustainable Supply Chains.

AI Use in Supply Chain Management still Low

To date, progress in digital supply chain integration is still slow. According to Gartner's 2022 Supply Chain Digitalization Survey, 28% of integrated technology companies, which include advanced e-commerce retailers, were using AI and data science platforms. For manufacturers, the percentage dropped to 15%, and among all companies in the survey, only 10% were using advanced analytics.

In such an environment, digital freight brokerages, who have tried to integrate transportation data from end-to-end, have struggled to make an impact. Convoy, one of the technology leaders, even went out of business when automation gains failed to keep up with technology costs. Others, such as Uber Freight, are trying to set an example in their own operations by integrating existing databases, SQL queries, correlation analysis, and regression models, under the umbrella of new generative AI solutions.

Large Retailer have become Forerunner of Sustainable Management

Given these challenges, it is not surprising that large companies with long supply chains are leading the way in improving productivity and sustainability by integrating AI technologies into their existing Supply Chain Management (SCM) systems.

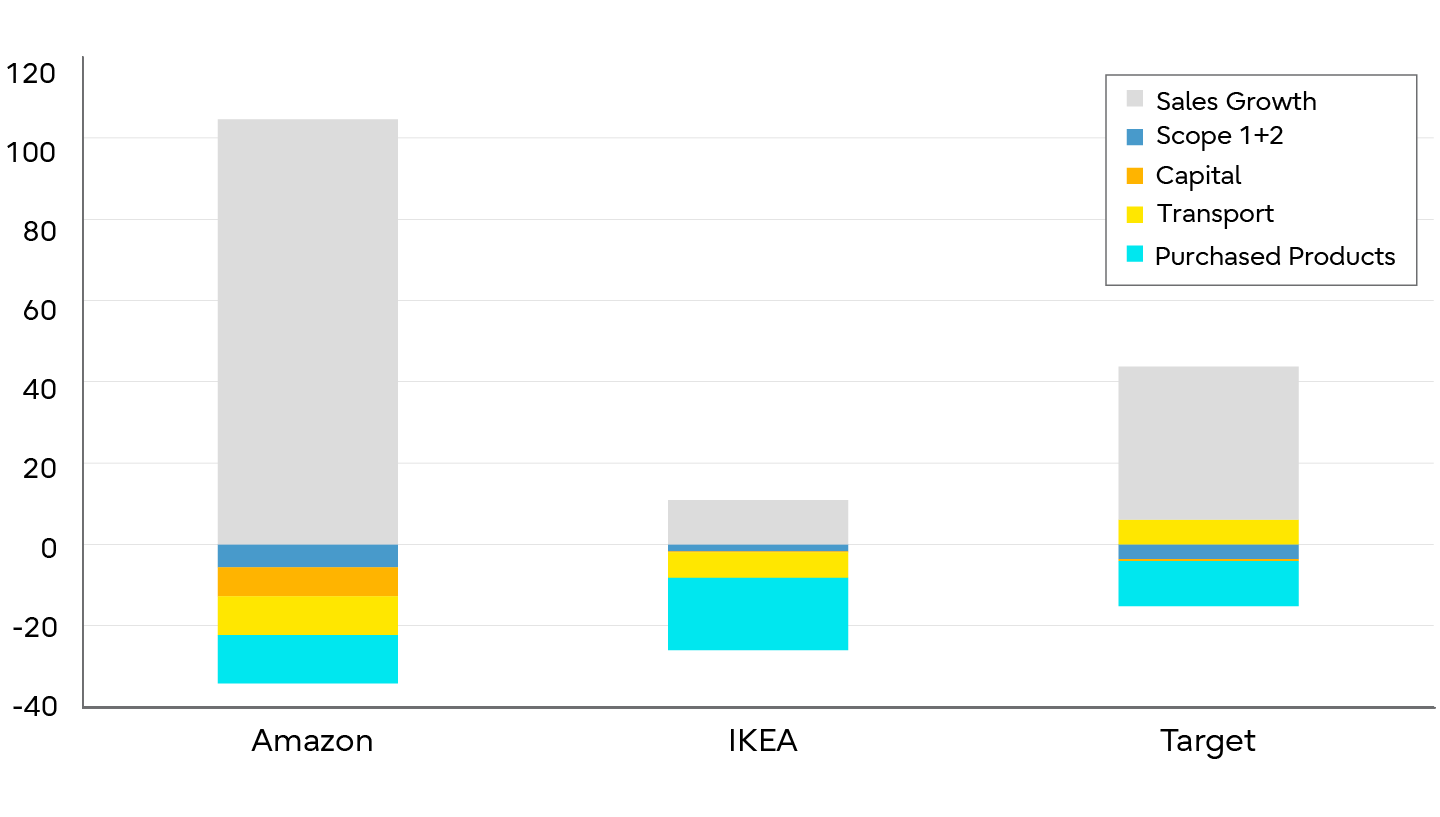

Gartner reports that AI engineering leaders among suppliers can generate at least three times more value from their AI investments than the rest. To illustrate the development, the figure below shows the revenue growth and the relative emissions (reduction) change between 2019 and 2023 for three retail leaders: Amazon, Ikea, and Target.

Supply Chain AI-Leader Emissions and Sales Growth (2019-23; %)

Note: For comparability, emissions are calculated as Emissions Intensity by dividing tons of CO2e by sales per 1000 USD.

Source: Corporate Sustainability Reports.

All three companies are using advanced AI platforms for demand forecasting, inventory management, warehouse optimization, route optimization, and service customization to improve productivity growth.

They have also added AI-enabled capabilities to improve sustainable operations, particularly energy and waste management. Amazon has added sustainable packaging, as well as warehouse and data center energy management capabilities. Ikea has integrated flexible and efficient micro-fulfillment centers into its supply chain. Target has installed sophisticated energy management solutions in its stores.

Amazon, as an e-commerce company with strong cloud platform operations, has been most successful in reducing emissions. It has been able to build new capabilities into its growing operations and leverage its own AWS platform, which offers a wide range of AI services. Its CO2 emissions intensity (CO2 divided by revenue in USD) fell by 34%, while revenue grew by more than 100%.

However, while Amazon's relative success has been driven by the use of renewable energy in its data centers and the integration of demand management with increasingly sophisticated logistics, it still falls short in the increasingly important effort to reduce supply chain emissions from purchased goods of its supply chain partners.

Partner Support and Improvement of Transport Emissions are Key

To achieve strong progress in sustainability efforts, Amazon focuses on its own logistics and products. It only reports its own branded products as emissions for its Scope 3 or "Purchased Products" reporting. These products account for only about 1% of the traded product sales on its platform and are much easier to optimize.

IKEA, on the other hand, has achieved a huge reduction in emissions for all of its purchased products. By tightly integrating its entire supply chain across all countries, it was able to make such gains.

At the same time, Target has been challenged by increasing transportation emissions as it has had to report more comprehensive emissions data from its traditional suppliers' transportation services, which has increased reported emissions even though some initiatives may have achieved improvements.

The three companies demonstrate the positive impact of smart improvements in internal operations and logistics, but also the importance of working closely with supply chain partners. Only when data and technology are shared effectively, and partners work together to improve end-to-end supply chains will the overall environmental performance improve significantly.

Challenges for Smaller Enterprises

While even supply chain leaders are challenged to improve sustainability, more traditional and smaller suppliers are struggling. Because most suppliers cover only a small part of the value chain, they have rarely invested in improving their data governance capabilities. Relying on busy humans to unload trucks, make phone calls for confirmations, and send emails for orders, automation remains a challenge.

Unfortunately, support from large customers in manufacturing or e-commerce to improve digital systems often stops at the gates of their Tier 1 partners and does not trickle down the supply chain. As a result, for most smaller companies, supply chain sustainability reporting requirements add cost and bureaucracy, but do not provide significant opportunities unless they can become integrated into larger approaches and supply chain initiatives.

Support from Industry Initiatives and Research

To find the right strategy, companies need to stay abreast of evolving new ecosystems and industry initiatives for data integration and information sharing.

For example, Fujitsu in Japan offers a logistics data conversation and sustainable supply chain integration service that integrates the government's "Logistics Information Standard Guidelines" with AWS cloud services. It can automatically transform and standardize logistics data formats from multiple disparate systems in a supply chain. This can become the basis for AI analytics services or data integration with customers' core systems and multiple logistics systems, such as WMS or TMS (Warehouse/Transport Management Systems).

Another example is the global Virtual Watch Tower (VWT) initiative, a digital orchestrator for the maritime industry's supply chain and logistics based on advanced AI integration. It is being developed by a collaboration between research institutes in Sweden, Finland and Singapore as well as technology companies such as Fujitsu. These logistics control towers will be able to support end-to-end logistics and supply chain monitoring by sharing private data enriched with public data

Yamato and Fujitsu Demonstrate Sustainable Logistics Potentials

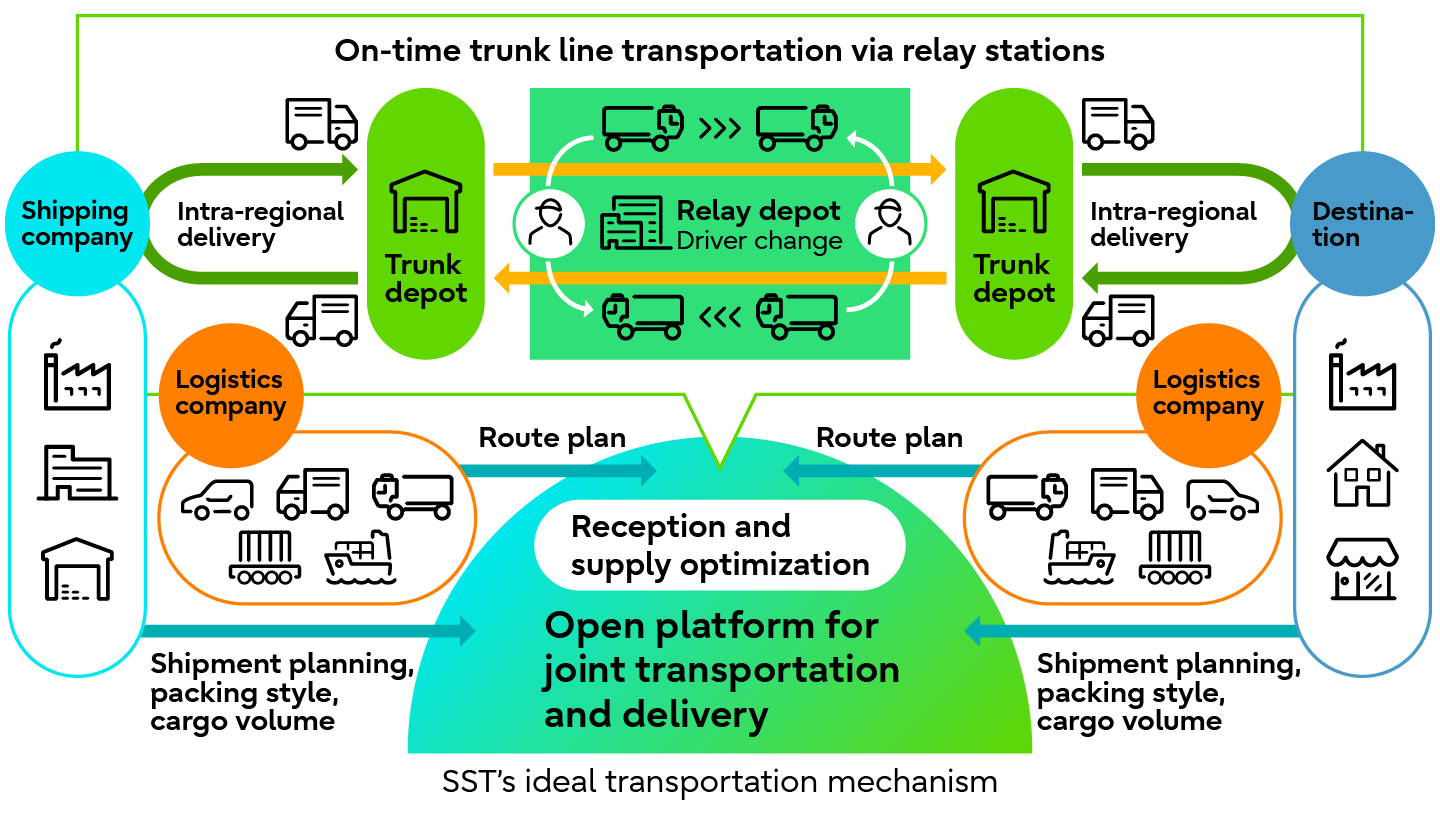

In Japan, the initiative has already delivered results. With support from Fujitsu, Japan's largest and most efficient logistics and home delivery company, Yamato Holdings, has established a new company, Sustainable Shared Transport Inc.

It provides an open platform for shared sustainable supply chains and transportation for its 1.6 million corporate customers and more than 4,000 logistics partner companies. By placing relay points with data access for all partners on an initial 80 routes, optimized volumes and packaging for each part of the end-to-end transport can be planned and optimized for each partner.

AI-Orchestrated Transport Logistics with Relay Points

Source: https://www.yamato-hd.co.jp/english/news/2024/pdf/newsrelease_20240521_en01.pdf

By the end of fiscal 2025, the company expects to reduce GHG emissions by 42% and labor costs by 65%.

Conclusion

More Generative AI-based initiatives are now opening the door to intelligent supply chain integration. With a common purpose driving coordination, supply chain operations can be aligned with sustainability goals as their driver. Sustainable AI development alliances can help develop algorithms that optimize delivery routes, reduce the environmental impact of warehouses, and orchestrate automation. Ensuring sustainable on-time delivery can help set new standards for efficiency-and new opportunities for the businesses that are connected to them.

Editor's Picks