DX Is An Opportunity to Deliver Sustainable Manufacturing

Fujitsu / May 25, 2022

Sustainable manufacturing is coming, says Johan Carstens, Head of Smart Manufacturing, Fujitsu North America at Fujitsu, but is change happening fast enough?

Sustainability is an imperative and an opportunity

The manufacturing industry is increasingly on-board with the sustainability agenda driven by the climate emergency. Change is visible in the number of manufacturers now operating within the UN’s Sustainable Development Goals (SDGs) framework, with Environmental, Social and Governance (ESG) policies in place to set tone and direction. This shift is already widespread across larger businesses — by mid-2021, 95% of S&P 500 companies had detailed ESG information publicly available — and is now percolating through to all levels.

Manufacturers have got the message. On one side, there is changing consumer behavior — favoring products with a credible sustainable agenda. Employees, investors and customers want to feel good about the ethics and practices of businesses they work in, invest in, and buy from. Businesses genuinely seek to be good corporate citizens. On the other side is an increasing level of government regulation to limit carbon emissions and reduce environmental destruction. Net-zero policies, which will profoundly affect manufacturers in the next investment cycle, are now in place in 130 countries.

And then there is the extraordinary rise in energy and raw materials input costs resulting from Russia’s invasion of Ukraine. Bloomberg recently reported how the cost of manufacturing household goods in Asia is being driven higher by surging energy and commodities prices. Energy has doubled from about 10-12% of total costs for European petrochemical crackers to about a quarter since the end of last year, according to ICIS, a commodity data business,

Reducing energy and raw materials usage is a key objective for many aspects of sustainability, with the result that driving forwards on this agenda has strong commercial benefits as well as an ESG component.

Businesses genuinely seek to be good corporate citizens

Sustainability is a DX objective

With this alignment of interests, Fujitsu’s research shows that manufacturers are already going beyond ESG policies towards concrete actions and investment. We asked over 200 manufacturing sector ICT decision-makers across 17 countries about actions taken so far and their plans. We found they are giving prominence to responsible, sustainable business practices, with Digital Transformation (DX) playing a central role in achieving goals in this area.

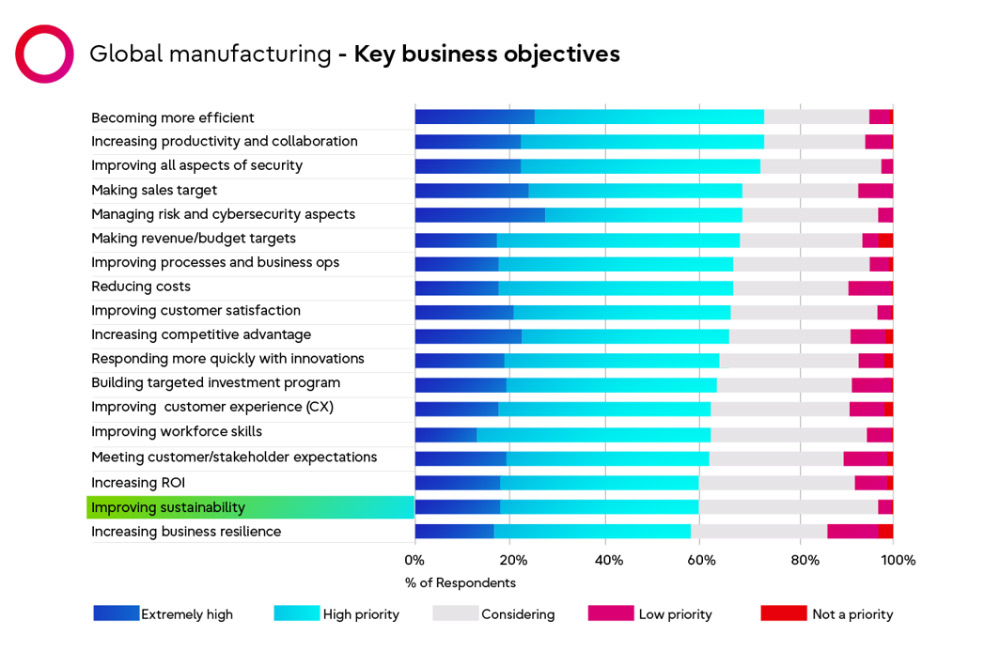

Conducting business in a sustainable manner is moving up the priority list, although it is still lower than it should be to meet the changing needs of society and consumers. Almost two-thirds of respondents consider that improving sustainability is either an extremely high or high priority and around one-quarter more are considering prioritizing it. However, improving sustainability is still ranked only the 11th highest priority for manufacturers, from a list of 28 business objectives.

Global manufacturing – key business objectives

Changing spending priorities

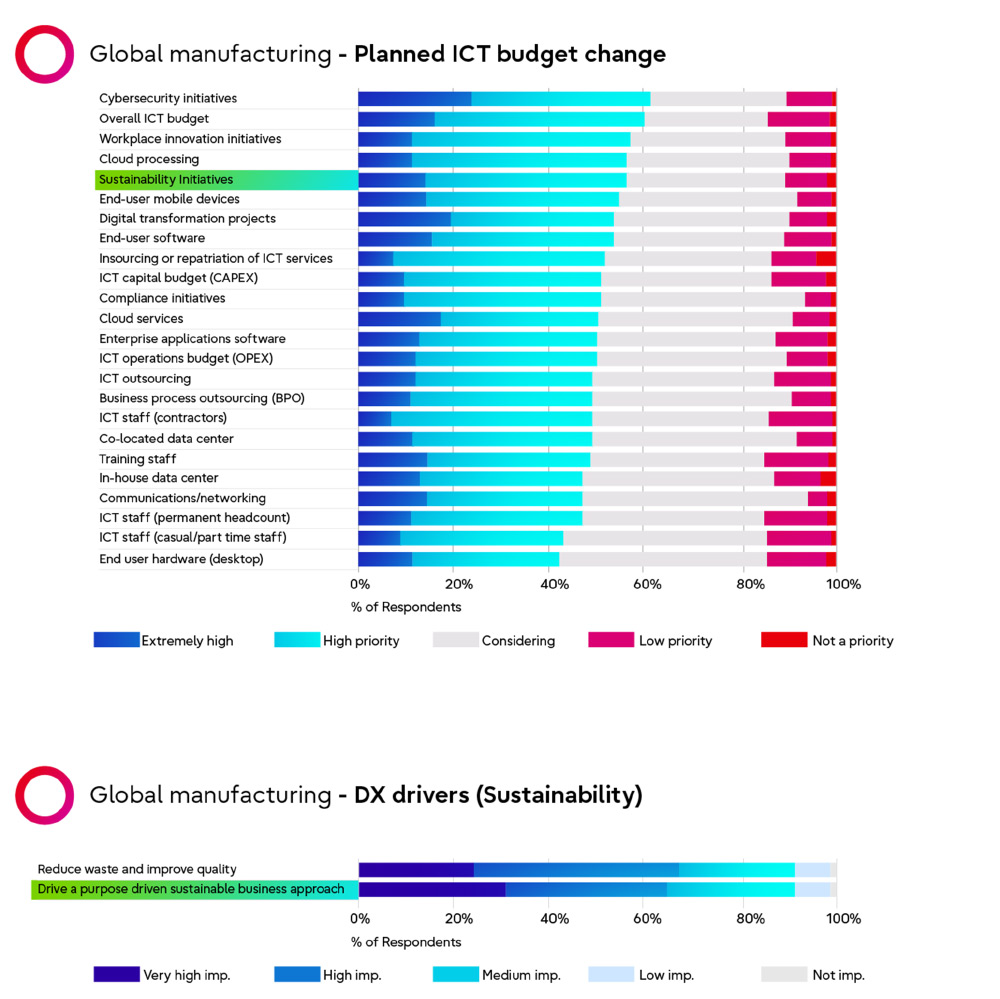

These changes are driving a shift in spending priorities, where sustainability goals are driving higher spending on ICT. Respondents rate environmental and sustainability regulations as well as diversity and inclusion considerations as having a powerful positive impact on their ICT spending. They rank these as the fourth and third most important factors driving ICT budget increases. Almost 60% of manufacturers planned moderate or significant budget increases for sustainability initiatives, with most of the remainder set to maintain budgets at current levels.

In general, sustainability is a big motivator for DX initiatives in the manufacturing industry. More than 90% of respondents say “a purpose-driven sustainable business approach” is of very high, or high, or medium importance as a driver. In fact, sustainability is the DX driver that most respondents consider to be of very high priority. Related to this, reducing waste and improving quality is the fourth most important driver of DX for manufacturers.

Planned ICT spend and sustainability as a DX driver

Manufacturers are already reducing waste

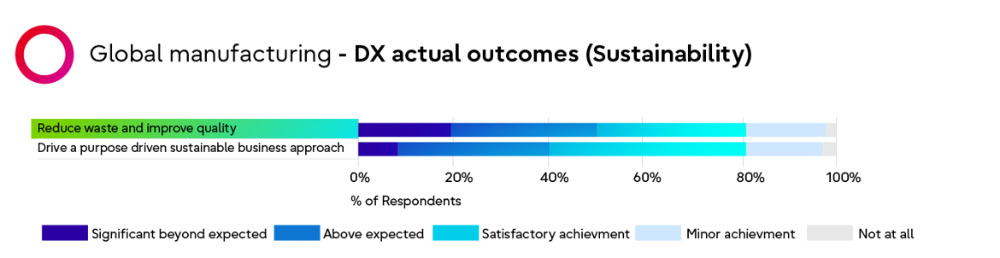

Manufacturers are targeting reduced waste and improved quality as an outcome from DX initiatives, and on top of that, also actually achieving it. Reduced waste/improved quality was the most successful outcome from all DX initiatives (half the respondents reported results above or significantly above expectations, and another 30% reported satisfactory outcomes). The outcomes for “a purpose-driven sustainable business approach” were strong, with more than 80% of respondents reporting satisfactory outcomes or above (40% achieved results above expectations).

Nevertheless, most products being manufactured today still have massive potential for greater efficiency and waste reduction. As technologies advance, we find new ways to achieve reductions in energy use and other forms of efficiency improvement that were simply unavailable before. To take one example, Fujitsu, itself a manufacturer, recently announced the potential of AI and quantum-inspired computing to reduce overall system CO2 emissions from mobile cellular base stations by 50% or more compared to conventional systems – while offering users high-quality, stable communications.

Actual DX outcomes in terms of sustainability

Remaining challenges

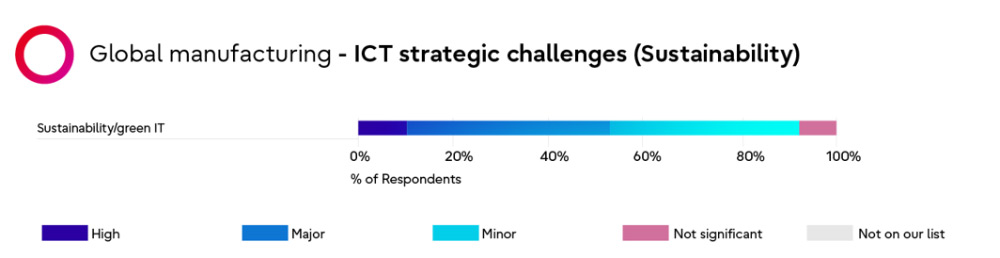

Despite positive signs in Fujitsu’s research, there is still some way to go. Manufacturers are starting to prioritize sustainability objectives and achieve positive outcomes from DX initiatives focused on sustainability. However, they still have challenges in migrating to more sustainable ICT approaches. More than half of respondents say sustainability/green IT is a major or high challenge and approximately 40% say it is a challenge, albeit a minor one.

The planned investment increases in DX-led sustainability initiatives show that the manufacturing industry is on the right track, but there is much more to do. To find out how Fujitsu can help your manufacturing organization develop an ICT strategy to support your organization’s sustainability agenda, contact me to discuss the many opportunities for sustainability-led digital transformation.

To read the full research report, click here.

Click here to see my video interview with Craig Baty from DataDriven, where I discuss how manufacturers fix sights on sustainability and social responsibility outcomes.

ICT strategic challenge in terms of sustainability

Explore manufacturing insights that benefit people and the planet

Sustainable Manufacturing

Fujitsu introduced a key focus area called ‘Sustainable Manufacturing’ as a part of its business brand, Fujitsu Uvance.

We support sustainable growth and the coexistence of nature and humankind through innovation in manufacturing, industry, and across the supply chain.

Related information

Editor's Picks