“Sustainable Manufacturing” in the VUCA era: Manufacturing in harmonywith the planet

Fujitsu / March 2, 2022

Fujitsu recently introduced a new key focus area called ‘Sustainable Manufacturing’ as a part of its new business focus, Fujitsu Uvance.

We talked with Shunsuke Onishi, EVP, Vice Head of Global Solutions Business and Head of Private Enterprise Solution Business Group at Fujitsu, who shared how Sustainable Manufacturing aims at circular and traceable manufacturing that benefits the environment and people while continuing the capability to produce.

(Fujitsu ActivateNow2021 Key Focus Area Sessions)

Challenges that the manufacturing industry is now facing

In the VUCA (*1) era, the path to survival is to remain flexible, and swift to respond to unpredictable changes that we have not faced before.

What priorities should management set up in the world of increasing uncertainty and diversity? What kind of effort is required?

10 years ago, many of the issues that we face today were considered as threats for the distant future.

But in recent years, the huge natural disasters which bring significant damage with them, have significantly increased.

Challenges that Manufacturing Industry is facing

Climate change

A recent survey shows that the number of disasters has increased.

In Japan, the economic loss from Typhoon #19 in 2019 was 1.65 trillion yen (approximately US$15 billion), the worst losses globally.

It is predicted that the global temperature will rise by 4 degrees Celsius by the end of this century, and that sea levels will rise by 82cm.

In Japan, it is forecast that flood possibilities will rise 4-fold.

COVID-19

Covid-19 changed our life a lot: the acceleration of digitalization, as well as the pandemic rebound, brought us a shortage in semiconductor products. One market survey forecasts sales losses of 23 trillion yen (the equivalent of US$200 billion) in 2021 among automotive companies alone.

Newly heightened international political risks

The intensifying political confrontation between the United States and China is putting increasing pressure on manufacturers to secure critical materials and natural resources. The supply of rare metals which are indispensable to the manufacturing industry has become an urgent issue and as has disrupted supply chains.

Imbalances in the workforce and loss of master craftmanship

Shortage of labor, and skills shortages are now one of major issues for developed countries. In Japan, more than 40% of companies say that labor shortage is one of most important management issues – that’s for both large enterprises and small-to-medium size enterprises. In the United States, there are the extreme cases of job mismatches between job employers and job seekers. Furthermore the aging labour population and the lack of succession cause a loss of craftmanship and know-how. This is becoming a real issue.

Immediate need for actions on decarbonization

Most developed countries are now setting targets for a carbon-neutrality society and putting in place actions to hit their targets.

Business leaders should see these measures as a trigger to explore new business opportunities. Under those circumstances there is increasing uncertainty in the market forcing drastic changes in management.

5 Solutions to the Challenges in the VUCA era

So, what are Fujitsu’s recommendations to help address these challenges? Here are five strategies that Fujitsu considers key, from it's decades of industry expertise.

Our Solution to the Challenges

Visualization to enhance decision-making linked to corporate activity

Firstly, what we need to do is to develop a holistic view, through visualization, of all corporate activity from engineering design through to manufacturing and covering the whole supply chain. From that point we can establish an infrastructure that allows management decisions to be made based on data. In this way, an organization’s management style can move from the rigidness and dependency on an original plan, and instead it can now be flexible to changes that happen and take corrective actions immediately.

Automation and skills transfer using robots and AI

Where there are challenges created by labour shortages or skills gaps, we recommend the implementation of automation and digitalization using robots and AI. Taking this path enhances the skills of the employees you do have and covers your current labour shortages. This will also enable you to establish a succession plan for technical skills, techniques and the know-how of skilled workers who may be retiring.

The current working situation of “all must be on-site” is no longer sustainable and you should be looking to establish a combination of remote and on-site set ups. This will make it possible to expand your regional business environment even during the Covid era.

Total value chain optimization of traceability and supply & demand balance

New business models such as D2C (*2) and OTA (*3) will help you adopt quickly to market needs which are diversifying rapidly. Circularity rate, or the percentage of material re-use is only 9% globally. Being able to trace materials and products from end-to-end is also becoming crucial as we seek to reduce waste and optimize demand and supply. We need to change that trend in the use of waste.

To improve in this area, we need to consider our collaboration and partnering with other companies. The key considerations here are that joint infrastructures, between our partners and ourselves, must be trustworthy and most importantly secure from the increasing security threats that we all face. This new joint-infrastructure also needs to be flexible enough to change configuration when faced with a threat.

Introduce resilience into the supply chain to be able to recover immediately from unpredicted risks

It is hard to predict or forecast global societal and environmental challenges causing by pandemics, natural disasters, political confusion and uncertainty. What is for sure is that our customers increasingly expect us to be able to recover supply chain almost immediately – despite all these unpredictable challenges – supply chain resiliency is our way of combatting uncertainty.

Visualization and reduction of Greenhouse Gas emission through entire value chain

New changes in international law working towards a carbon-neutrality world mean that companies who are not able to provide the necessary certification will face severe penalties, and also a threat to their businesses ability to continue.

Monitoring greenhouse gas emissions in all business process will lead to a reduction in greenhouse gas. This will also make it easier to identify the cause of problems and take the necessary action to maintain carbon-neutrality compliance.

Towards the realization of sustainable manufacturing where people and the earth coexist

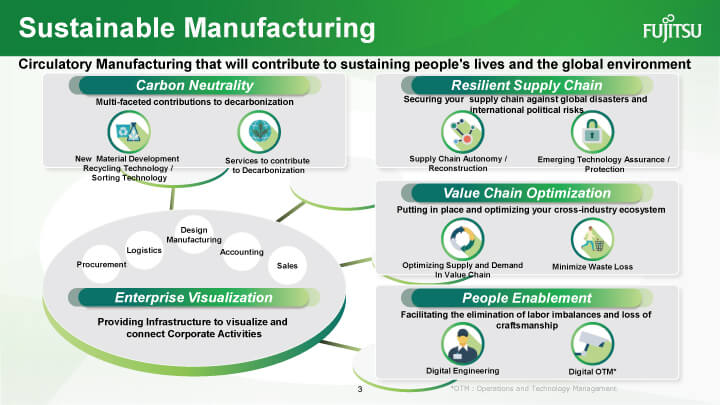

Fujitsu has defined “Sustainable Manufacturing”, as the future vision of Manufacturing. Our manufacturing values are based around 5 themes:

- “Enterprise Visualization” - the ability to visualize corporate activities and provide connecting foundations across the entire supply chain.

- “People Enablement“ - helping to forecast labor imbalances and consequently predict where there may be a loss of craftsmanship as a result.

- “Value Chain Optimization“ - putting in place and optimizing your cross-industry ecosystem.

- “Resilient Supply Chain“ - securing your supply chain against global disasters, international political risks and unpredictable eventualities

- “Carbon Neutrality“ - the many ways and multi-faceted contributions we can all make towards decarbonization

Sustainable Manufacturing

Fujitsu is at its heart a manufacturing company.

Through our deep manufacturing experience, we have established the Cyber Physical System which uses digitalization technologies. We have lots of practical know-how that has come as a consequence of developing that system. Our experience is built on proposing and implementing manufacturing solutions as well as collaboration schemes to companies in both engineering and supply chain areas. The understanding that we have developed of end-to-end operations and the entire supply chain that’s involved in manufacturing is where Fujitsu can provide real value to our customers. From initial design to production line manufacturing, our know-how translates into the highest levels of optimization and being able to solve any trade-off issues a customer may need to make – for various scenarios.

In addition to strategic collaboration with global partners like SAP and Siemens, our most trusted technologies which include High Performance Computing, AI and security will be powerful tools in a world that brings such uncertainly to the industry of manufacturing.

Industrial know how, experience and advanced technology – these are the values that we bring to you as a global technology leader.

We are pleased to partner with you and we look forward to working together towards "Sustainable Manufacturing".

(*1) VUCA:VUCA : Volatility, Uncertainty, Complexity, Ambiguity

(*2) D2C:Direct to Consumer

(*3) OTA:Over The Air

Vice Head of Global Solutions Business and Head of Private Enterprise Solution Business Group

Fujitsu Limited

Related information

Editor's Picks